"One must learn by doing the thing, for though you think you know

it, you have no certainty until you try".

--Socrates

"One must learn by doing the thing, for though you think you know

it, you have no certainty until you try".

--Socrates

Location Corporate Office:Flying "M" Stock Farm

14560 Madison Run Road

Gordonsville, VA 22942

(540) 672-3094

cmyersaero@aol.comSolomons Island Office:

523 Oyster Bay Place

Dowell, MD

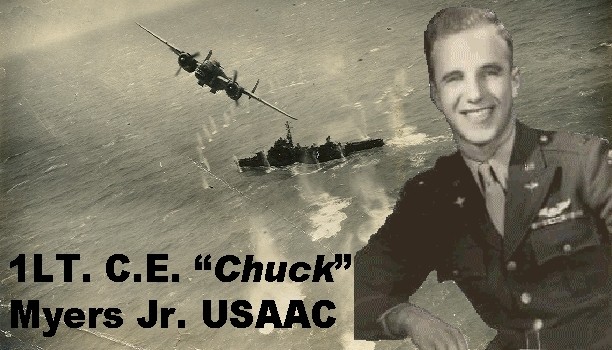

(410) 326-3319President: C.E. "Chuck" Myers, Jr.

Secretary: Sallie Northrup Myers

Webmaster: Carol Murphy

Company Focus: Identifying Operational Deficiencies for Prospective Combat Situations, Exploring Affordable Technical Opportunities to Enhance Combat Capabilities, Creating a Dialogue with DoD/Congressional Leadership Toward Adopting Effective Combat Forces, Transforming the DoD Acquisition Process, Education of the Public, Congress and Services re the Essence of Operational Effectiveness of Standing Forces for WAR

Website: www.aerocounsel.com

also: production of organic beef (non-profit operation)

DEFENSE TRANSFORMATION: BACK TO THE FUTURE?

The Department of Defense (DoD) is a complex and high visibility government

entity which, because of its vital role and significant budget, will always be

a prominent target for criticism by legislators, management pundits and other

government agencies. The DoD is subjected to continuous reviews and

attempts by outsiders and incoming administrations to "improve" its

internal processes, especially the manner in which it develops and acquires

new weapon systems. The latest advice on acquisition comes in the form of the Joint

Defense Capabilities Study of December 2003 directed by the Secretary of

Defense and chaired by former USD (AT&L) "Pete" Aldridge.

It expands on and complements findings of past reports such as the 1970

Blue Ribbon Defense Panel "Fitzhugh Commission" Report to the

President and the Secretary of Defense, the 1972 Report of the Commission

on Government Procurement, the 1975 Report on Acquisition of Major Systems,

the 1978 Report on the Acquisition Cycle by the Defense Science Board and others

too numerous to list. These reviews contain considerable wisdom from the experience of the

participants and if the recommendations were ever implemented the

performance of the department would doubtless improve. Implementing change

however, has proven to be a formidable challenge. In

addition to these numerous reports, the evaporation of the Warsaw Pact threat

forced a change in focus and amplified the complexity of operating in a

multi-polar world; this coupled with the experience of Dessert Storm prompted

calls for a Revolution in Military Affairs (RMA) and a "transformation"

of the Armed Forces. Who are the advocates for "transformation"? And, itís

fair to ask, transformation to what? In addition to declarations by the President, Members of Congress and the

Secretary of Defense, it turns out that many who have been "in the

trenches" of the uniformed services and civilian branches of the DoD and

industry long for a return to "the good olí days".

Ergo the suggestion, "Ö. back to the future." It is not surprising that some advocates of change will recount how: In past eras, it was not uncommon for senior officers to make on-the-spot

decisions, launch combat actions or radically alter plans and operational

objectives without first consulting with a CINC or the JCS or State or the

White House. And, in the defense acquisition arena, there were times when the concept

for a new flying machine progressed from "idea" to experimental

hardware in less than a year, and sometimes even into production within

three or four years without appearing in a JROC, without creating programmatic

and political turbulence and without breaking the bank. The Quadrennial Defense Review (page 68) states that we need a DoD wide

reform of the planning, programming, budgeting, and acquisition processes.

It further calls for new operational concepts, new capabilities and for an emphasis

on experimentation and training. Is there evidence that anyone is

listening?

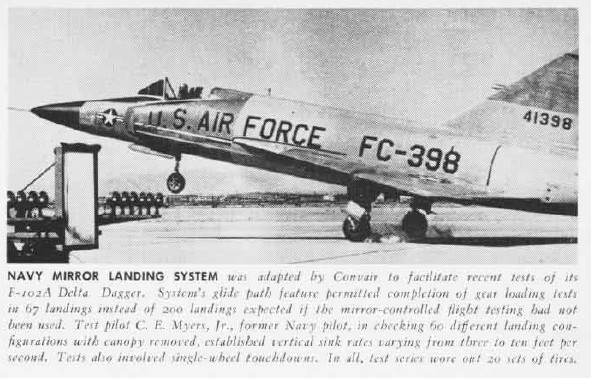

I remember experimentation as something we "used to do a lot" without great fanfare and not just in response to a proclaimed Presidential National Commitment (ala Star Wars) for a proposed heavily financed development program. For instance, in the mid fifties there were always a half dozen military aviation experiments in process. As a young test pilot, one I participated in was the Navy XFY-1 VTOL Pogo Stick. And, at Cornell Labs, colleagues were flying a machine with rotating engine nacelles (vectoring thrust), while at CONVAIR, Sam Shannon was shooting "splash and gos" in San Diego harbor with a delta winged sea based jet fighter on skis while Don Germerad was struggling with the big contra-rotating, turbo-prop R4Y amphibious Navy patrol airplane. At Pax River, Cdr. Victor Utgoff was testing the Martin amphibious "supersonic" mine-laying patrol aircraft as Pete Gerard of Ryan was demonstrating the Avon jet powered delta winged vertical take-off/land "Vertijet" in front of the Pentagon River entrance, a spectacular show to say the least. None of these aircraft were procured but neither were they considered "failed" experiments for from them we learned a lot.

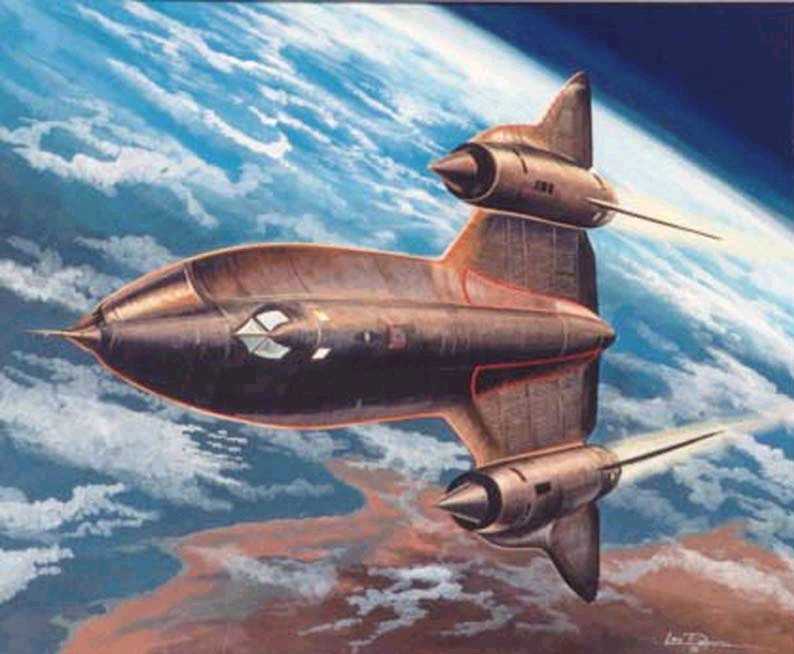

During this era, Kelly Johnsonís "Skonk Works" at Lockheed in Burbank was designing and flying the Mach 2 F-104, the high flying U-2 (which nobody knew about until it was shot down over Russia) and they were beginning on the SR-71 Mach 3 reconnaissance "Blackbird", all without SPOís or "spiral development", a MENS, a ROC or approval by a DSARC or DAB or even the Congress.

The diversity and level of activity kept a number of young design teams "spun up", sharp at their trade and competitive. Termination of an experimental program (many never progressed beyond the experimental stage) was not traumatic for either the sponsoring service or the industry ---- both learned from the experience and pressed on toward the next challenge.

The cost of these projects was less than what we spend today just on program definition or issuing and responding to an RFP. The reporting obligations were miniscule compared to today ---- a heavy reporting burden is time consuming (expensive) and contributes little to the product of experimentation. In that era, our engineers were generally limited to K&E slide rules for calculations. So, logically, one might assume that with todayís CAD technology, we should outperform those ancient design cadres, that is, we should get it done quicker, better and for less cost, right?

At this point, its fair to ask: "what happened to the DoD acquisition process since the fifties?"

The best I can do in response to the question is recount what I observed. In 1962, I hung up my test pilot "g-suit" and came to Washington as an aerospace contractor with ideas about what the USAF and Navy needed for the future and an eagerness to "help" make it happen. Little did I know I was entering the scene at the beginning of a period of "unintended transformation" of the defense acquisition process.

In those "good old days", I could ride a cab to the River or Concourse entrances of the Pentagon and just stroll in without an ID, usually getting to visit whoever it was I wanted to see, and often, without an appointment. Off site conferences were held over a "contractor financed Martini and Crab Salad lunch" just five minutes away in the private Windjammer Club atop the Marriott Twin Bridges overlooking Washington National Airport where we were served by lovely young ladies in appropriate attire. Military and OSD guests abounded; everybody seemed to have time for fun as well as serious discussion, even the "big guys". If you wanted more formality, you could dine with senior Air Staff officers at Place Vendome in D.C. which was orchestrated by a very proper French hostess, Jeannine; every fighter pilotís target.

With little warning, acquisition process management and participation became less fun for service leaders and staff because of an imposed "new look" which featured heavy OSD involvement. Secretary of Defense Robert McNamara was hired by President Jack Kennedy to alter the process and product of Defense Acquisition. The Presidentís defense spending guidance was to assure that the tax payer got the most "bang-per-buck". That was the invitation for the application of "cost effectiveness (C/E) analysis", a nightmare to military and industrial leaders who had grown up in a "requirements/procurement by-the-seat-of-your-pants" process. Charlie Hitch reigned as the OSD Comptroller and his Director for Systems Analysis (SA) was an articulate, perceptive and confident economist, Dr. Alan Enthoven. You may have heard tales about how this SecDef and his chief "Whiz Kid" terrorized Generals and Admirals but the real agony was for the military and industrial underlings who were compelled to work with some of the stars of the Systems Analysis staff like Victor Heyman and Dr. Deiter Schwebs (former engineer/analyst on Adolf Hitlerís missile program). And, along with C/E came Life Cycle Costing (LCC) and the PPBS criteria for program definition and funding justification.

The response to the "new mode" was for each of the services and companies to create their own SA organizations to reformat an "operational requirements" based case into accepted C/E models and vernacular. The comfortable "gut feel" expressions of operational requirements began to reappear in the form of irrevocable formula subject to audit and with results which could hardly be altered once supported by a ton of computer printout.

Relative to abandoning the "cut and try" mode of R&D for the precision of SA, it is appropriate to consider a quote attributed to Dr. Albert Einstein: "If we knew what we were doing, we wouldnít call it research, we would have a different name for it". And Socrates: "One must learn by doing the thing, for though you think you know it, you have no certainty until you try". Such observations were foreign to the systems analyst ----- if you couldnít quantify it, it didnít exist. If you like metrics; they had metrics ---- for everything. SA cleared the "fog of war" and, at least in their minds, removed uncertainty and risk from the development of new equipment.

Now, revisiting my paragraph about the many simultaneous experiments that were happening in our 1950ís R&D "playpen": do you think that we believed we knew how our favorite project was going to turn out? Did we have a clue about the probable LCC of an envisioned system or could we explain where it was going to fit within the total force capability for the next thirty years? Are you kidding? Of course not!

However, you recall I said that we performed those "whimsical" experiments for "not much money". Factors which contributed to the tolerable cost portraits: (1) relatively few acquisition management regulations (2) a minimum of progress reports (once submitted, they become targets for review by Congressional factions, GAO, CBO, etc.; responding to such oversight creates overhead, bogs down project managers, discourages creative talent, multiplies man hours and drives up the cost while failing at the goal of assuring accountability). Such burden is totally out of sync with the purpose behind experimentation (probing for possibilities/discovering fallacy).

Oblivious to all this, behind the gates of Lockheedís "Skonk Works", Kelly generally lacked even a contract much less a SPO (Systems Program Office) and he had his own version of security (the most effective/lowest cost I have ever witnessed; example: the SR-71 was flying over the desert for three years before it was discovered). Visitors were not welcomed. Even corporate board members couldnít "drop by for a visit". He had no customer relations staff, he assured minimum distraction to his engineers and mandated low overhead. Progress reports were viewed as a security risk. He gave no assurances about equal opportunity employment nor would he respond to requests to explain his management style or plans. Is it any wonder that his aeronautical achievements are unlikely to be equaled?

WHAT HAPPENED? How did we "progress" to the current situation which prompts continuous challenge and review? What triggered the change?

Imagine working in an environment that invites innovation, encourages freedom of design, promotes competition, rewards initiative, etc. Now, lets abruptly impose a process that demands "precise" predictions of performance, effectiveness, future procurement and support costs as the criteria for a contract award or program approval. Might such a change invite prevarication? What else, since we canít know how our project is going to progress or what it is going to cost, and yet, the only way to keep it alive is to concoct optimistic technical and fiscal projections. And, when challenged by oversight analysts, we will spend valuable time warping facts to create an analysis which mitigates or shrouds our systemís potential weaknesses. Additionally, we may feel compelled to modify the design to be responsive to the whim of a powerful operational/technical dilettante, either civilian or military. Such responses will naturally increase the cost and/or reduce the utility of the product, all in the name of "program survival". After a few years of operating in this mode, the front end of the acquisition process evolves into a game of Military-Political-Analytical R&D Gymnastics on a grand scale. Sound familiar?

Assuming a military service can convince the Congress (often willing partners) to buy a product which evolves from government directed R&D and if it operates reasonably well in the hands of the OT&E user, it may possibly be procured in large enough quantities to yield a profit in spite of the entrophic process which produced it. In a worse case scenario, the producer privately hopes it will never be exposed to a war environment which could reveal flaws introduced by the compromises that were made to keep the program alive. The expensive and time consuming process which has evolved might be referred to as Covert Unilateral Disarmament (CUD).

After a number of years, the industry and the sponsoring services learned how to assure continuation of a program in spite of gross cost growth or marginal performance. The technique took on the name "political engineering". The DoD program manager, with cooperation from the "prime", distributes contracts to companies located in selected congressional districts so as to garner assured support from Congress. It soon becomes unthinkable to cancel an incumbent program merely because of the emergence of a better idea or that the threat which supported the original need has evaporated. And, there is little probability of cancellation for minor blemishes such as poor performance or a cost over run. At the same time, there is the myth that "defense is a zero sum game". However, there are numerous examples where additional funds magically materialize just in the nick of time to launch an overlapping program via insightful Congressional intervention.

During fifty years in Defense R&D (following participation in two Wars), I have experienced to spurts of success in outmaneuvering our ponderous acquisition process. Three examples where coalitions of OSD, military and industry activists induced things to happen which would not have otherwise include the: A-10 which evolved from the USAF AX program, the F-16/F-18 from the USAF Light Weight Fighter (LWF) program and the F-117 from DDR&Eís Project Harvey, none of which were initially in the "long range plan" or supported by the acquisition cadres of the services.

Eventually, the services became advocates for the products of these interventions that had (1) momentarily circumvented the system and (2) induced acceptance of concepts which clashed with existing plans and "service validated" operational concepts. It is interesting that thirty years later, one of the primary findings presented in the Executive Summary of the Aldridge report to the Secretary of Defense is that:

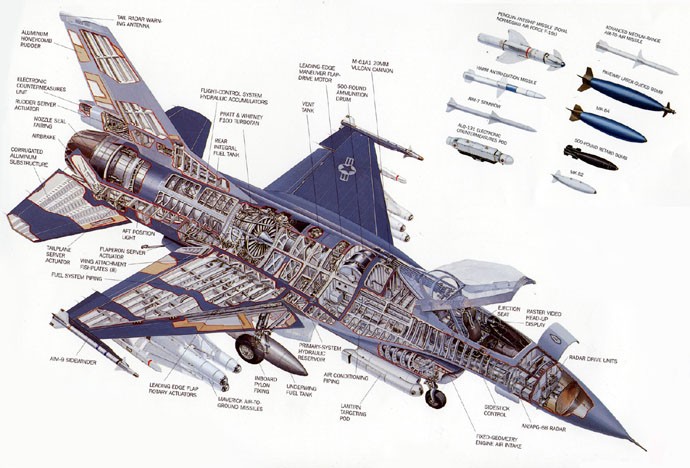

The original SPO for the LWF program (an experiment) was an obscure Colonel, two Majors and four other employees. The LWF RFP, guided by Col. John Boyd and the "Fighter Mafia", was 25 pages and the industry response was limited to 50 pages. Two prime contractors were selected from a field of five competitors. For less than $106 million (FY75 $) total project cost, GD and Northrop each created and flight tested (head to head competition at Edwards AFB) two prototype fighters which exhibited leading edge design, material and control technology. The demonstrated aircraft performance and the cost were so attractive that the NATO countries became heavily involved and the Navy was eventually badgered into participating --- both were major unintended accomplishments. Here is a classic case of the development and acquisition of a prime free world weapon system for which there was no documented/validated military "requirement". It is worthy of note that the Required Operational Capability (ROC) document for the F-16 was not written until well after production had begun at the General Dynamics, Fort Worth plant.

In response to the call for "transformation", I have attempted to suggest a possible goal by recounting "better days" and explaining, from my living experience, why/how that environment evolved into what we have today. Can we recapture the bubble? How might it manifest itself? What are the metrics which define it? What is the working environment for such performance? What were the leadership and management themes, attitudes and inducements which "permitted" such accomplishments? Is it possible to go back to the future? Is it worth trying?

Itís not unreasonable to suggest that those who would "transform" the DoD Acquisition Process revisit the anatomy of SR-71, LWF, AX and Harvey, all worthy programmatic profiles to emulate. Perhaps those experiences and the experiments of the fifties contain keys to restoring the environment that permitted such accomplishment?

And, as a last resort, we might ponder the observation of Dr. George Stigler, Nobel Prize Laureate from the University of Chicago and member of the Presidentís Blue Ribbon Defense Panel (page 198 of the report): "It does little good to reorganize every few years, expecting improvement. A good organization must have built into its very structure incentives for its personnel to do the right things."

__________________________________________________________________________

Originally written in 2004

An edited (cleaned-up) version was Published in the Navy Institute Proceedings in 2005

After thought, suggested reading: Blink by the author of The Tipping Point, Gladwell.

--Albert Einstein

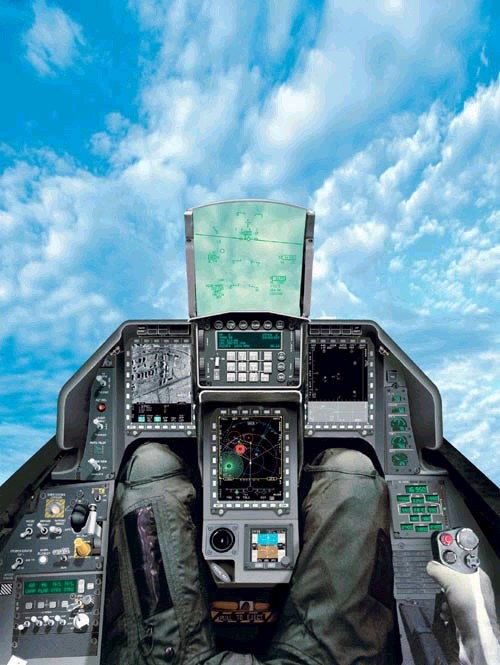

Armed Forces Journal (Click on thumbnail to view full-size)

1987

"Air Support for Army Maneuver Forces"

U.S. Naval Institute Proceedings

"Wars may be fought by weapons, but they are won by men."

General O.P. Weyland, USAF

"All that matters is force structure, force structure, force structure"

Patton's Air Force: Forging a Legendary Air-Ground Team, Washington. DC: Smithsonian Institution Press, 2002, Binding: Hardcover. Pages: xix + 377.

Air Support for Patton's Third Army. Sullivan, John J. Jefferson, NC: McFarland & Company, Inc, 2003 ISBN 0-7864-1465-0, 186 pages

General Claire Chennault, USAAF

http://en.wikipedia.org/wiki/Claire_Lee_Chennault

The P-40 in the CBI was not an obsolete aircraft. In fact held its own in every combat theater in WW2. Its weakness was a slow climb rate and poor flight performance above 20,000 feet. In fact including Allied High Altitude bombing 95% of air combat flying occured below 20,000 ft, right where the P-40 excelled. In fact in 1941 and 1942 the P-40 was the "modern" Fighter Aircraft in CBI. Even after the introduction of the Ki43, which met the AVG in combat April 1942.

The prime opponent of the P-40 was the Ki27 with a top speed of 280mph, 60mph slower then the P-40. The Ki43 top speed 310 mph, but 40 mph slower. In combat the P-40 B/C model had 3 times more fire power with 4-30 caliber and 2-50 caliber VS Japanese Ki27 and Ki43 2-30 caliber machine guns. When the E-model P40 arrived in April 1942 it was 6-50 caliber guns against 2-30 caliber. In 1943 the Japanese introduced better aircraft Ki44, Ki61 and Ki84. Below 20,000 feet the P-40 remained a competitive aircraft.

Chennault was a very astute judge of air combat. He used well tested strategies, tactics and rolling logistics which allowed the AVG to rack up an amazing score with minimal losses. The AVG and its later counter parts were rated one of the best, if not the best, Air Combat organizations in the world. Dan Fahey - Way of a Fighter, General Performance Data

Biographical Sketch for C.E. "Chuck" Myers, Jr.

In 1961, Mr. Myers created Aerocounsel, Inc., a mini-think tank to serve the aerospace community. Since then, he has consulted or worked for 16 aerospace companies, NASA, FAA, GAO, CNA, IDA, OMB, CSIS, DoD, USAF and USN. During the past forty years he has written and lectured about various military missions including air superiority, close air support, fleet air defense and fire support for ground forces. In 1978, he began the effort which led to reactivation of the Iowa Class battleships and much later, a Navy proposal to create a Battle Surveillance Airship to assist in air defense against the "sea skimmer" cruise missile threat. This was coupled with briefings on his Littoral Warfare study which illuminated the need for a dedicated "fire support ship". During 1985-2000, Aerocounsel, conducted workshops on tactical air support for maneuver warfare. He chaired forums sponsored by COMNAVAIRPAC which led to a novel concept wherein fixed-wing pilots perform as a self-adaptive cooperative element in support of infantry.

Mr. Myers had the unique experience of completing both Army Air Corps and Navy pilot training. He flew low-level attack versions of B-25s with the Fifth Air Force in the Pacific Theater in WWII, separating from the Army Air Force in October 1945. Chuck then served as an USAF reserve pilot while attending Lafayette College, graduating with a B.S. in Mechanical Engineering in 1949. He was then commissioned Ensign, USN and trained as a Naval Aviator, graduating in April 1951 and later joining VF-72 to deploy aboard the carrier USS Bon Homme Richard to fly F9F-2 Panther jets in the Korean War.

In 1954, Lt. Myers graduated from Navy Test Pilot School after which he flew as a Navy Test Pilot for nearly two years before resigning to become a civilian engineering test pilot for CONVAIR. His first assignment was to develop a new flight technique for the "Pogo Stick" VTOL Navy fighter. After this project was terminated for engine problems, he joined the CONVAIR fighter-interceptor test team at Edwards AFB, CA. During five years at Edwards, he served as President of the Society of Experimental Test Pilots, became Chief Test Pilot on the USAF F-106 program and flew the speed envelope extension necessary for the Air Force to capture the World Speed Record from Russia in 1960 at 1,544 mph. He later flew with the U.S. Army during early experiments using armed helicopters for fire support at Ft. Rucker, Alabama. In December 1999, Chuck was inducted into the Virginia Aeronautical Historical Society's Hall of Fame for his contributions to aeronautical progress during the past 50 years.

FEEDBACK!