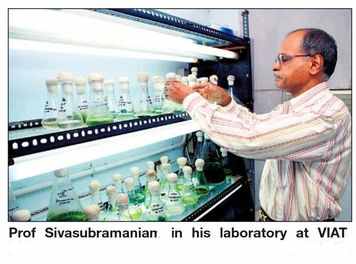

Reader and Phycoremediologist, Plant Biology and Plant Biotechnology, RKM Vivekananda College, Chennai 600004, India, and Director, Vivekananda Institute of Algal Technology (VIAT), Ramakrishna Mission Vidyapith, Chennai 600004, India. Ph: 091-044-24813960; Mobile: +91 9444003960; +91 9381487310