|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Kelley Island Lime & Transport Company

1887 - 1955 |

|

|

|

Back to Directory |

|

|

|

|

|

|

|

The Central Complex as seen in 1920 |

|

|

|

|

|

Formed in 1886 the Kelley Island Lime & Transport Company started its first quarry on Kelleys Island, which is only 3 miles north of Marblehead. The Kelley Island Lime & Transport Company or better known for its initials (KIL&T) began to purchase land on the penninsula in the late 1880's. By 1900 all of the once privatly own quarries were now bought out by KIL&T which looked at Marblehead as being the next large operation. In the beginning KIL&T was interested in the Lakeside & Marblehead Railroad. KIL&T was interested in shipping its products year around and rail was the key to the outside world. Soon after coming to Marblehead they were able to secure the railroad as a main parent company.

|

|

|

|

|

|

|

|

This 1920 picture shows the busy activity with the narrow gauge Shays. |

|

|

|

|

|

When the company first started operations on the Marblehead peninsula it used most of the existing lime kilns and quarries that were included with the land purchases. The first quarry to be purchased was the floundering Roesling quarry, kiln, and dock. Both Clemons quarries and kilns came next. And in 1910 the Ohlemacher quarry and its facilities were now part of KIL&T.

These quarries and plants continued to operate with the same employees but now working under KIL&T. Also KIL&T managed these operations separate, which kept things organized for the company. After the Ohlemacher property was gained, almost all quarries in Marblehead were now under KIL&T control. |

|

|

|

|

|

|

|

|

|

|

|

|

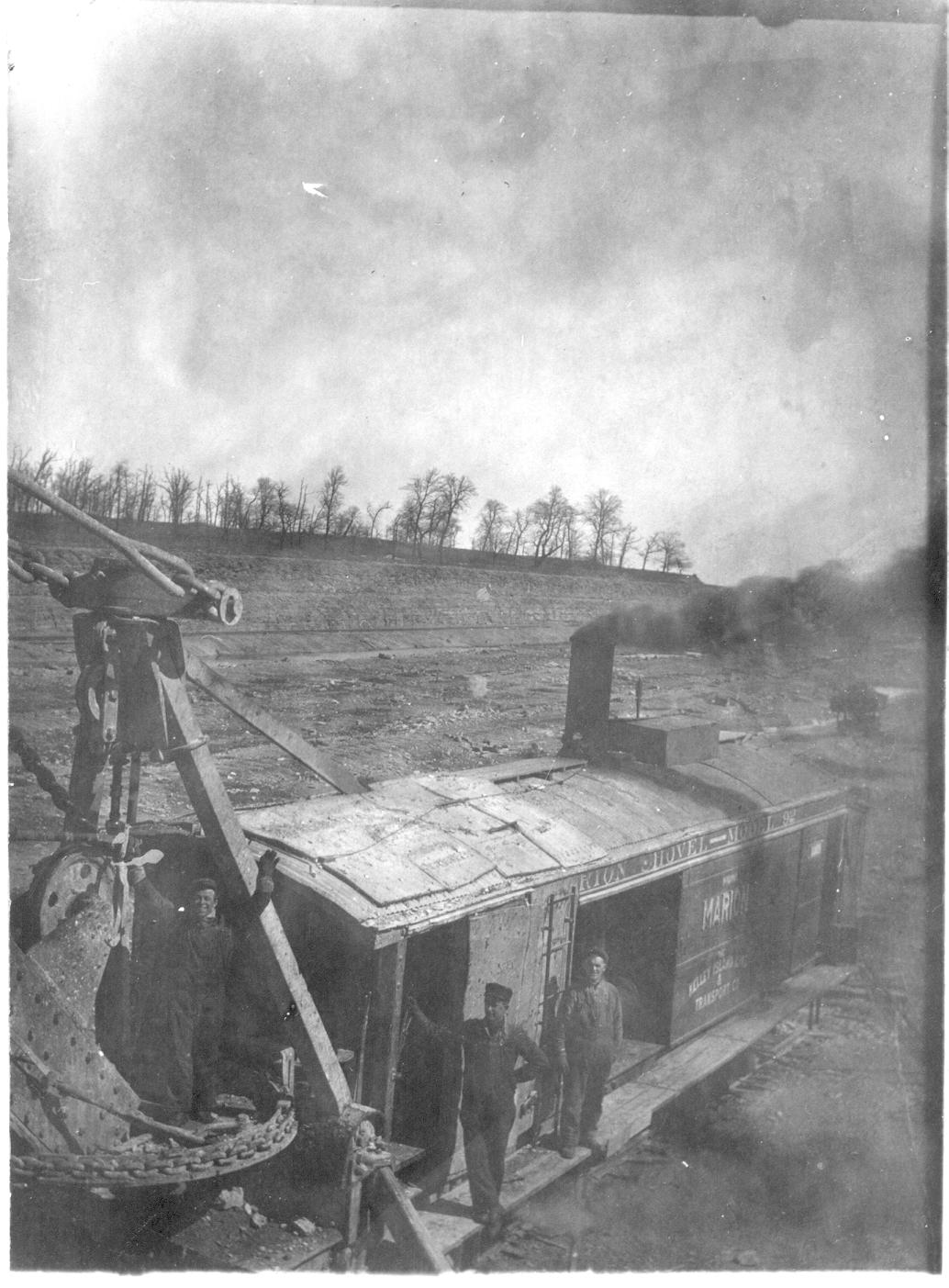

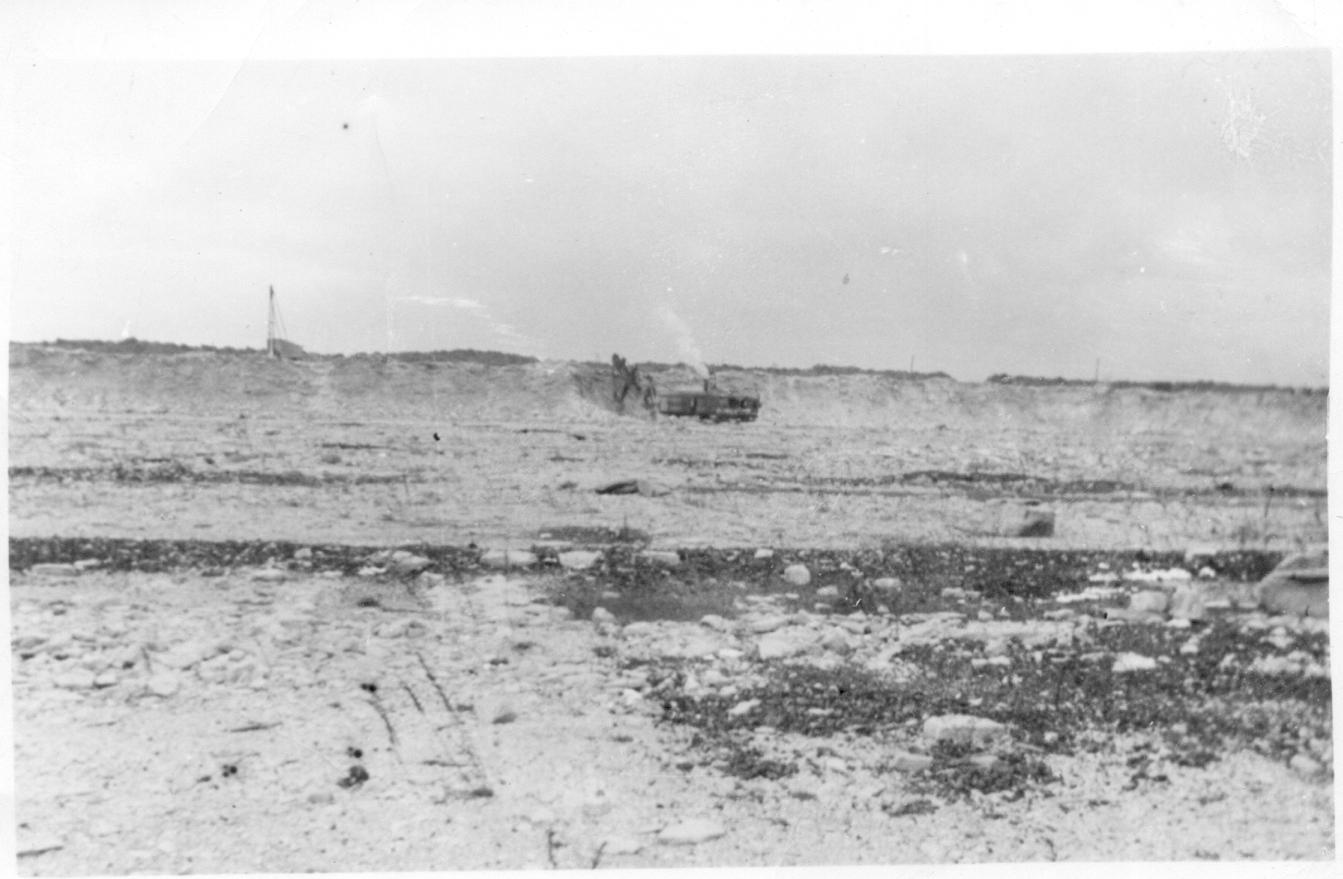

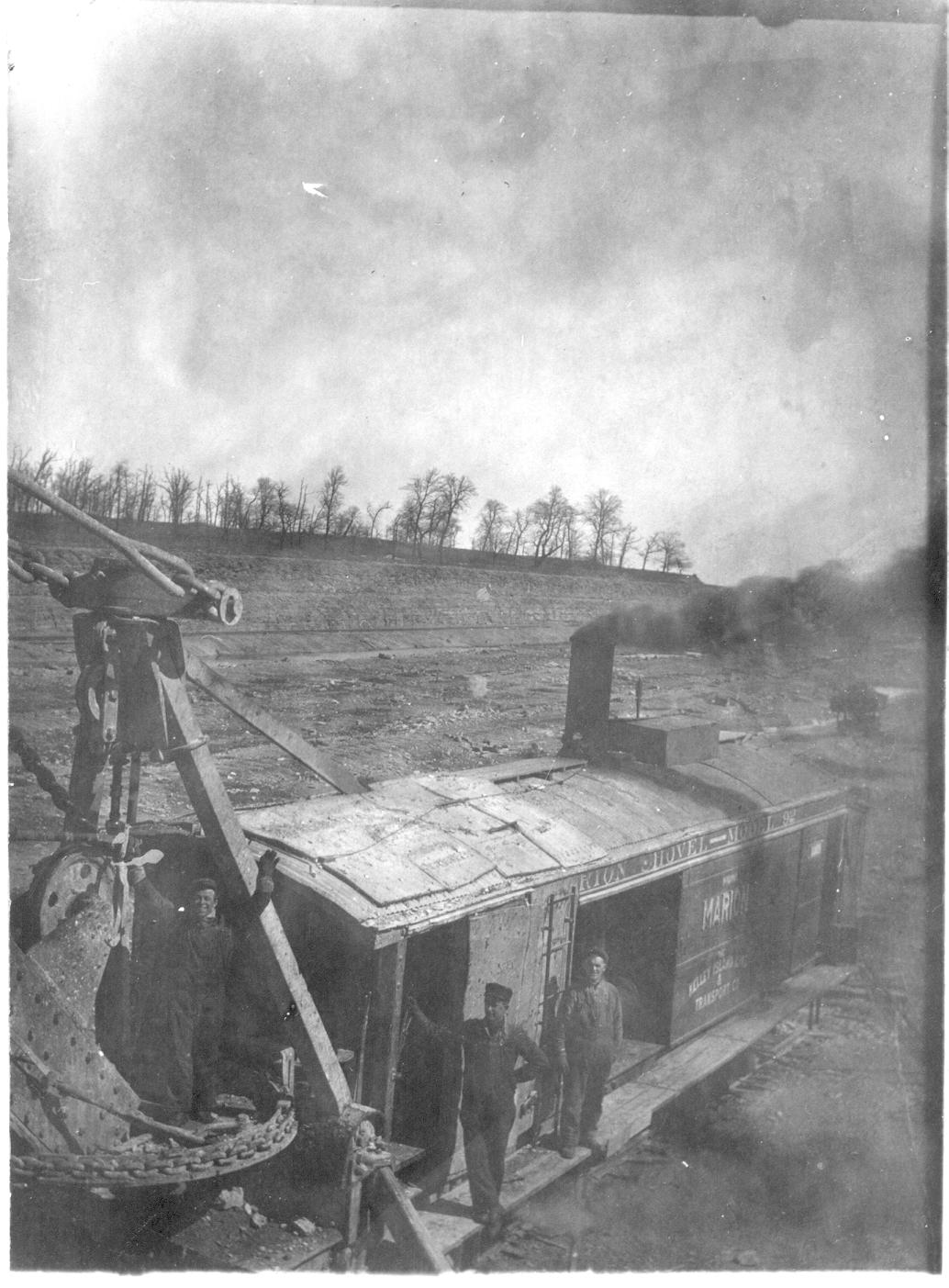

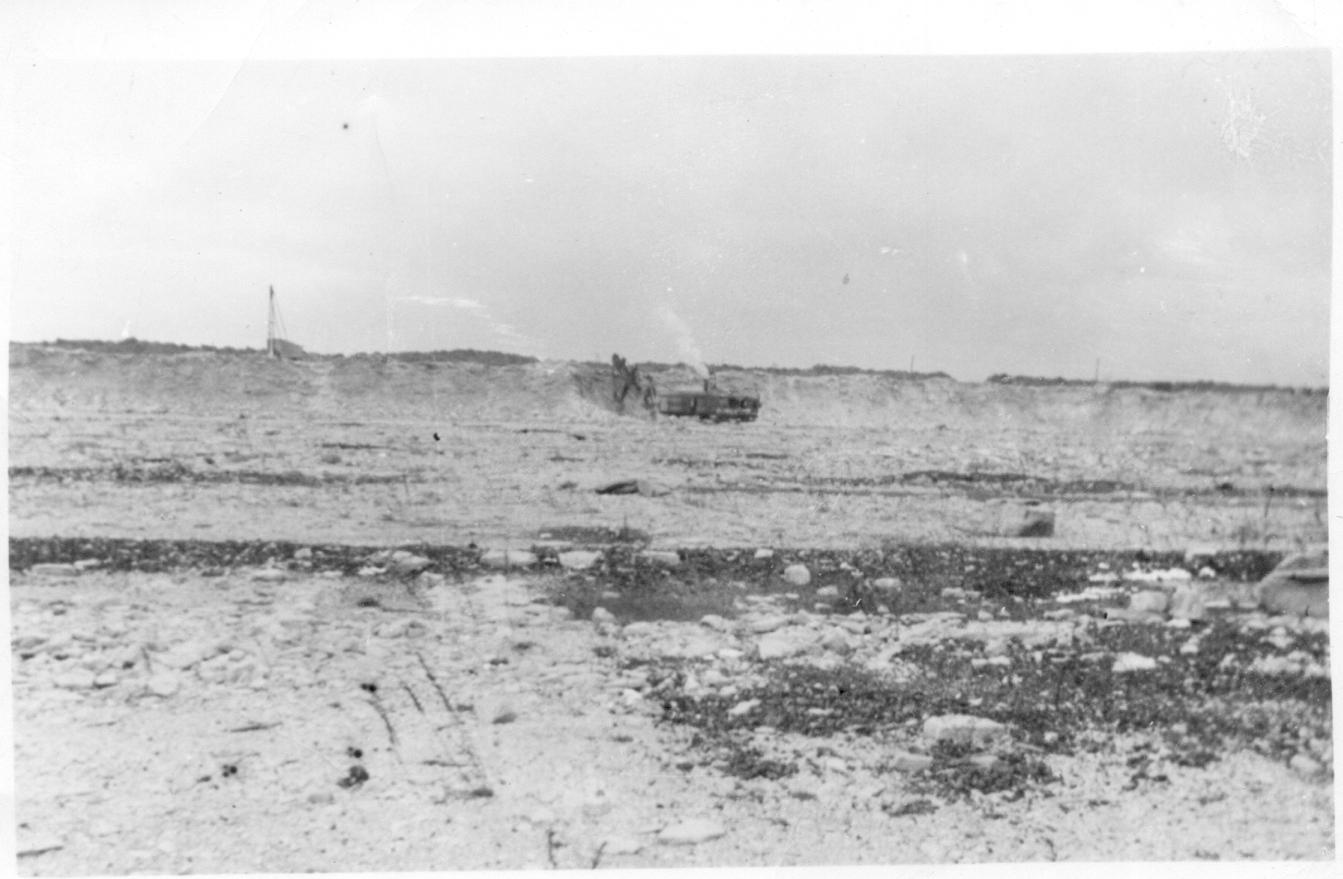

The main working face in 1920, this would been located near Lakeside. |

|

|

|

|

|

|

Marion Power Shovel Company was the main supplier of shovels for the Marblehead plant. |

|

|

|

By 1900 KIL&T currently had purchased over 2500 acres of property. This expanded to 3000 after 1920. KIL&T was always up with technology at the time. Quarrying was done with large Marion steam powered shovels which loaded small side dump stone cars pulled by dinky narrow gauge engines commonly called Shay locomotives. This was the same way quarrying was done at all KIL&T facilities, including Kelleys Island.

In 1895 KIL&T built a modern kiln facility and crusher in Marblehead, near the present day St. Rt. 163 conveyor crossing. Also around 1903 a large dual gauge (standard/narrow) enginehouse, shop complex, cooper shop, and concrete block facility was built in this area, making this the "Central Complex" for KIL&T. Around 1901 a new crusher was built south of Lakeside. This facilty was called Plant "B" and was just south of the Plant "L" kilns. |

|

|

|

|

|

|

This 1950 picture features Crusher "D" at one time the largest crushing plant in the world |

|

|

|

|

|

|

Operations in the quarry was fast paced to keep up with the steam shovels working the extraction ledges. Shay engineers were given assignment sheets at the begining of the shift on what shovel to load from and what facility unload at. KIL&T had up to 3 available crushers in the early days of operations. One being Crusher "A", B and "C". After the Ohlemacher purchase in 1910 that crusher too was used. KIL&T's first loading dock was the old Roesling stone dock, and then in 1910 shipments could be made from the Ohlemacher dock. Other shipments of lime and stone was done directly from the plants via L&M to Danbury Yard. In 1922 a new state of the art crushing facility was built south west from Crusher "B". This new plant phased out all three main crushing facilities. And was named the worlds largest crushing plant. More upgrades at the quarry continued as the fluxstone business soon started to replace on site lime making. |

|

|

|

|

|

|

|

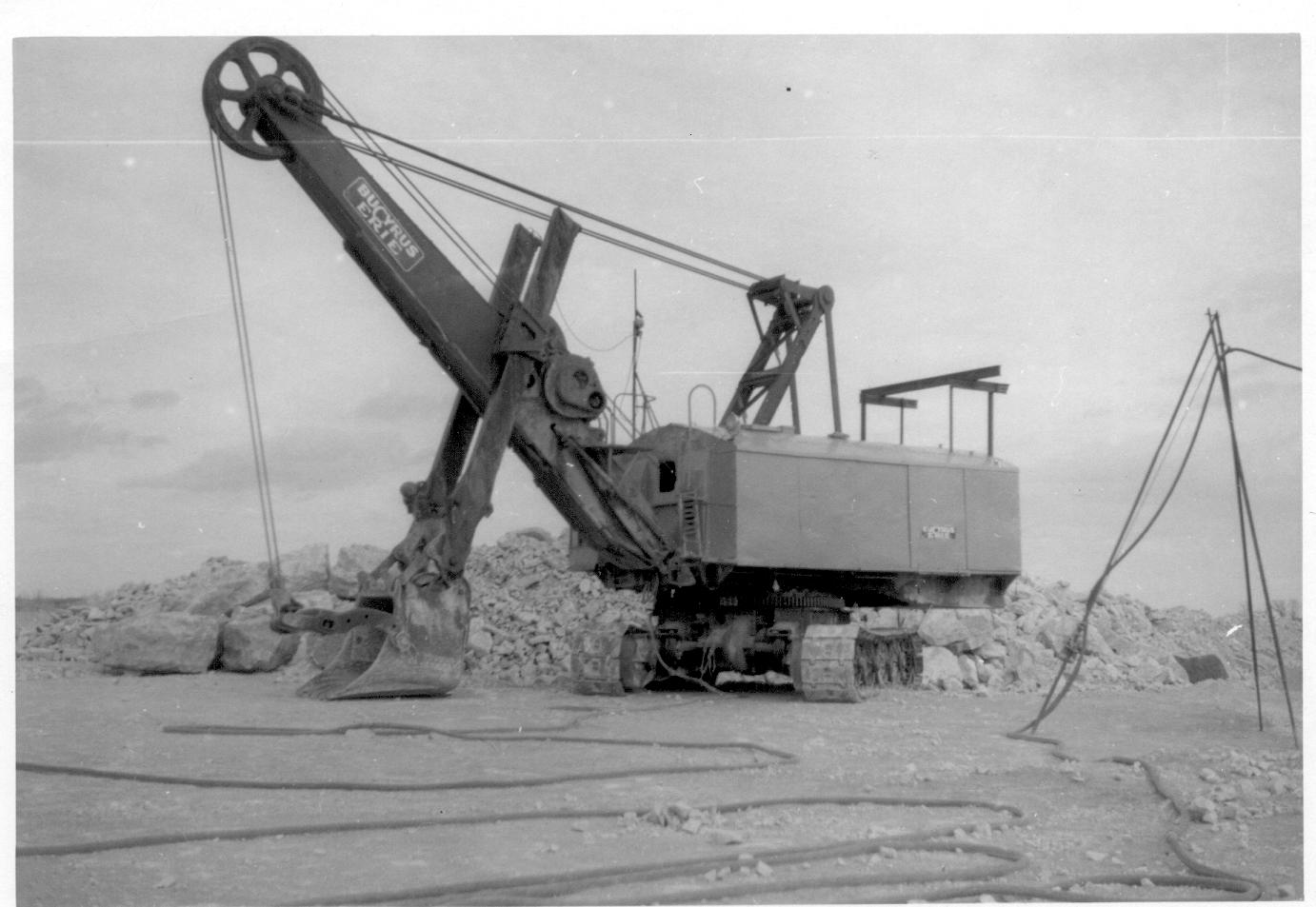

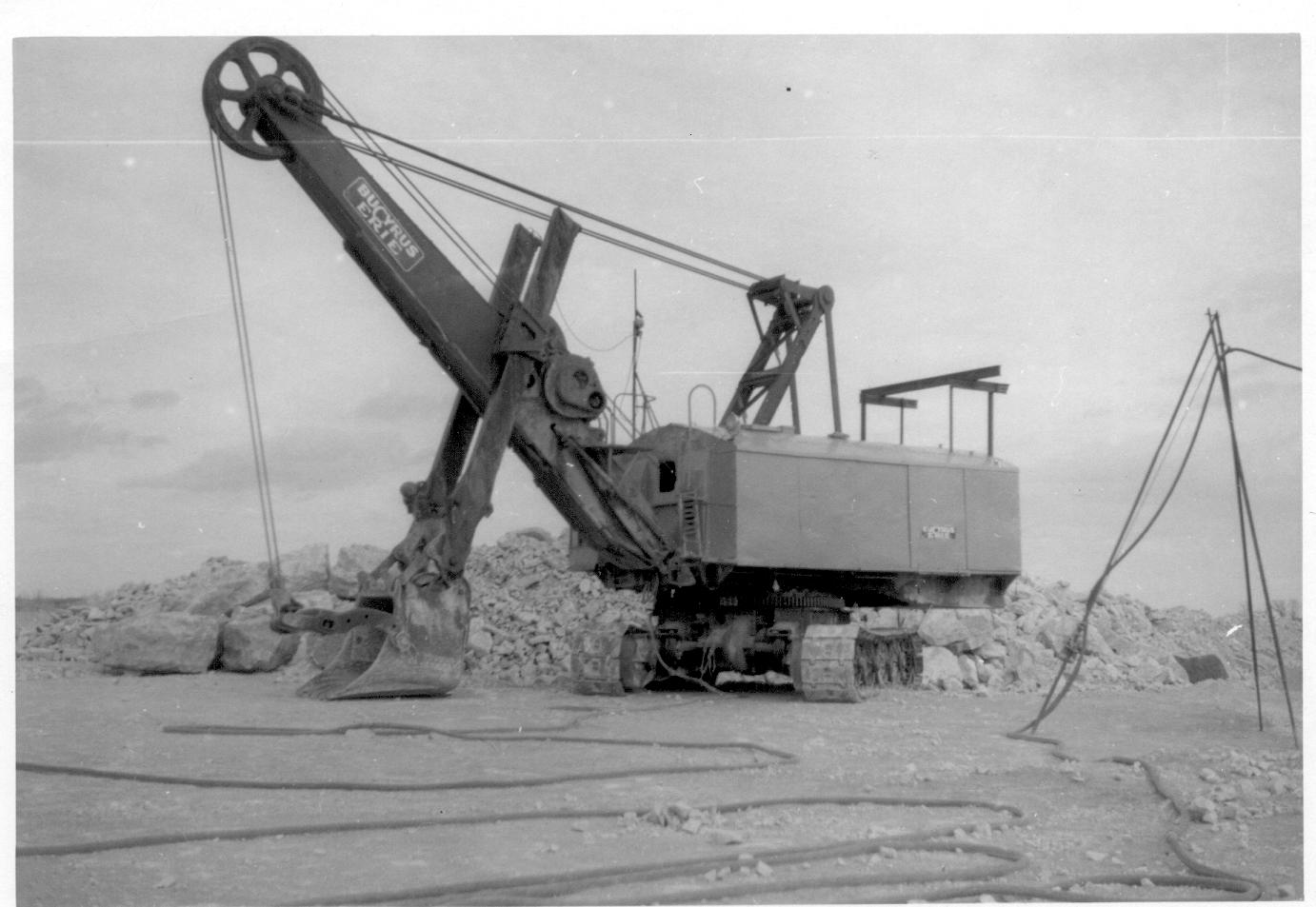

One of the Bucyrus Erie 150B electric shovels. |

|

|

|

|

|

Lake shipping was an important part of the quarry during the summer months. The old Ohlemacher Dock was insufficient for vessels and was the old Roesling dock which was nothing more then a wharf capable of loading barges. In 1928 a new loading dock was completed at the site of the Roesling dock. This new dock could load larger vessels, and also can handle more tonnage. At times the new loading dock would accomondate two vessels at the same time between loads of different size stone.

Every year the quarrying operation moved west, now in the area of Quarry and Hartshorn Road. By the time World War II started, the once mighty lime production in Marblehead ended. The Central Kilns was the last plant to produce lime before 1941. All existing lime plants closed at Marblehead.

|

|

|

|

|

|

|

|

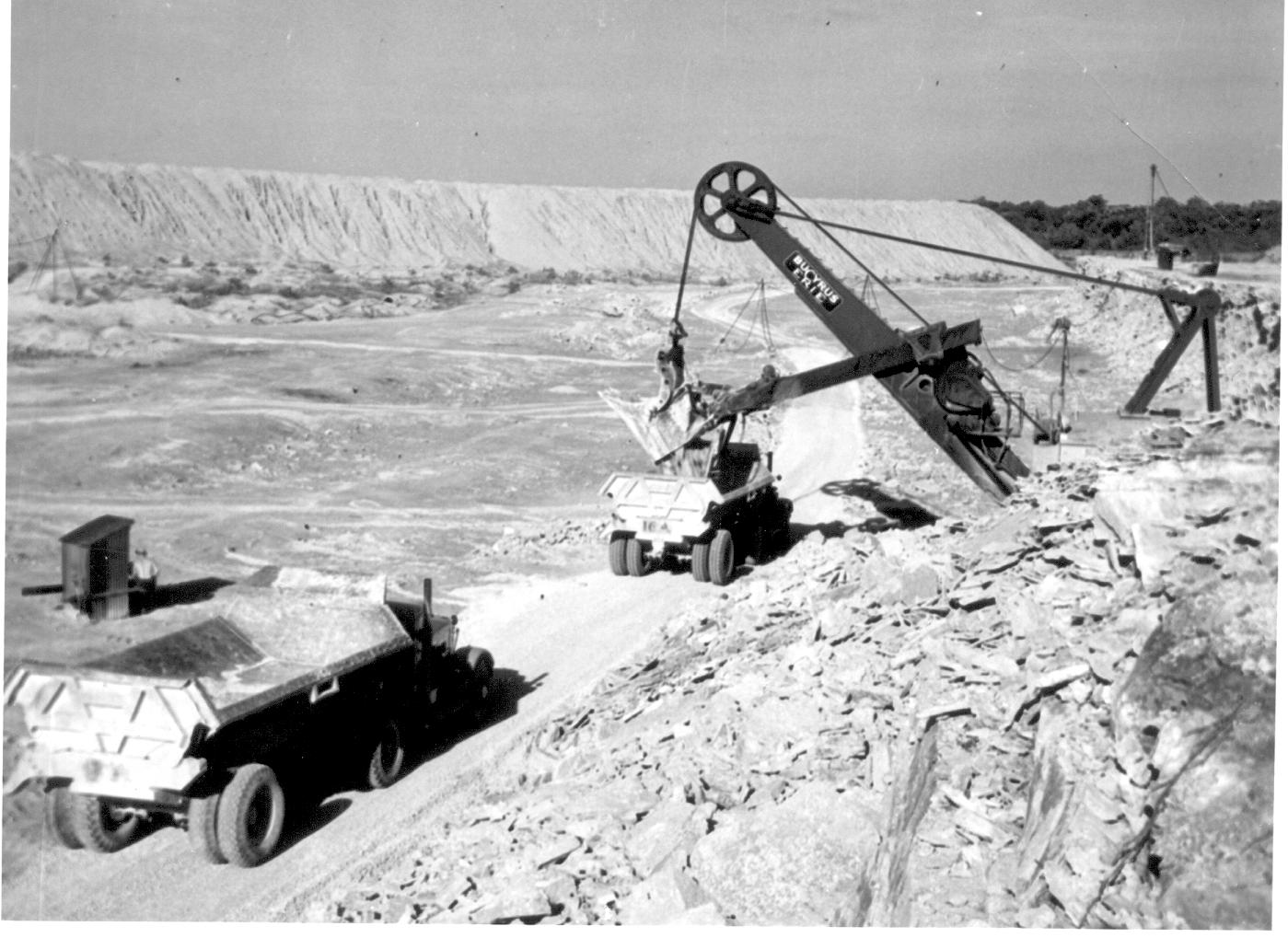

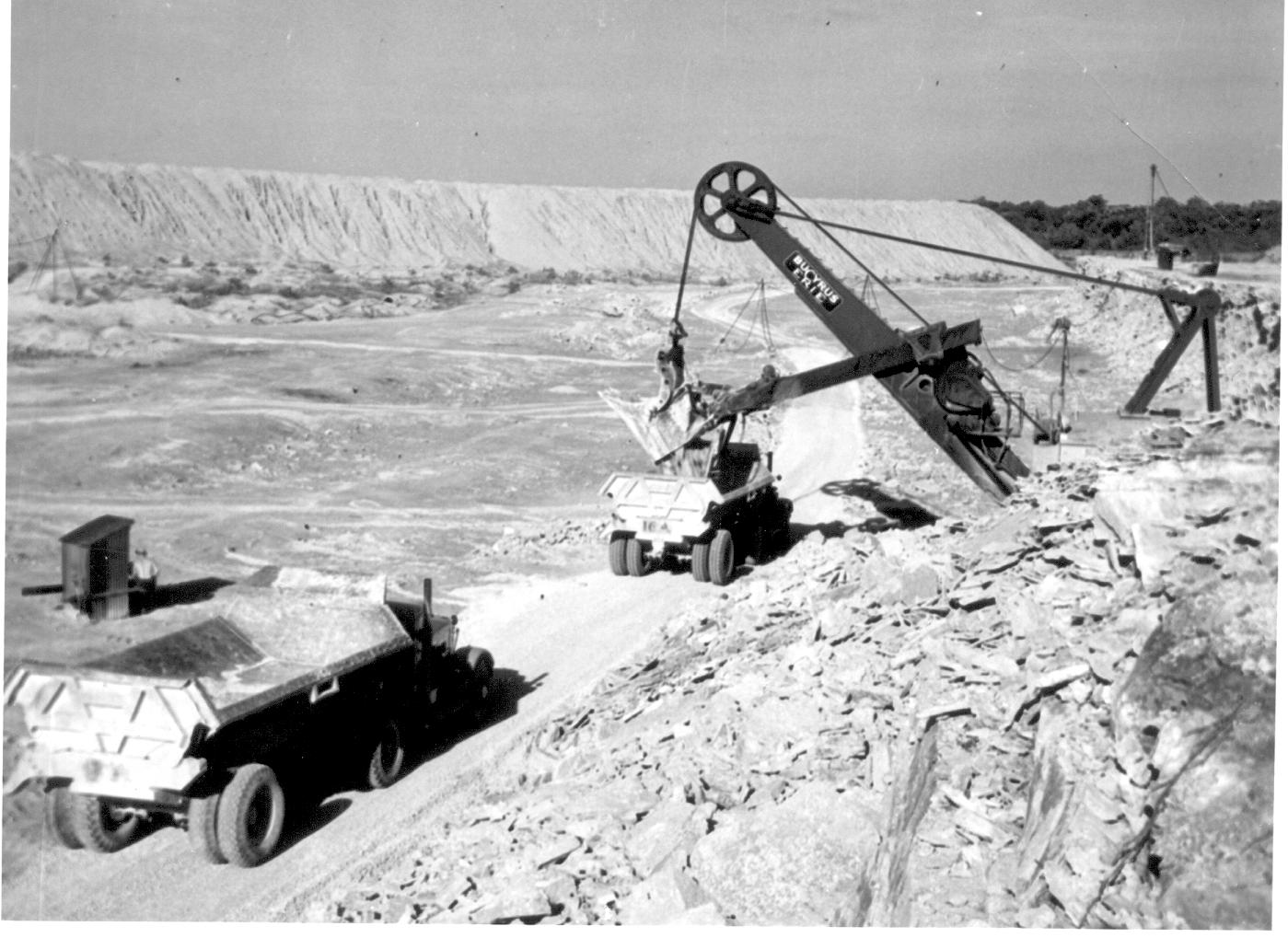

Loading Autocar trucks at the face in 1948. This location was close to Crusher "D' as you can see the waste screening pile in the background. This pile is still present today. |

|

|

|

|

|

Also landmark improvements began with moving towards truck transport in 1941. Truck transport would eliminate the narrow gauge shay engines and stone cars in the quarry. Most engineers would be moved from railroad duties to driving the new trucks. During the switch over almost all narrow gauge tracks would be scrapped including the engines and stone cars. The enginehouse near Crusher "D" was then converted to maintenance haul trucks. Mack tractor trucks were purchased along with 3 Autocar trucks. They were equiped with side dumped hauling units built by Easton Wagons. By 1943 the standard gauge steam shovels were replaced with 3 track driven Bucyrus Erie electric shovels. Buy 1949 20 Autocar DC10 tractors were used in raw stone hauling from the quarry to Crusher "D". This grew by 1951 to 26 Autocar tractors, and hauling units. In 1952 almost thirteen stone operations were owned by KIL&T between Ohio, West Virgina, New York and Pennsylvania. In 1953 KIL&T staff studied how much fluxstone existed on the property. The final answer came to about 10 years of stone left. In 1955 the quarry was sold to the Minerals and Chemicals Corporation of America. KIL&T continued to operate other operations until it disolved in 1960. |

|

|

|

|

|

|

|

Another view of the working face as Autocar trucks line up. Notice the rare view of a Caterpillar scrapper unit on the right. |

|

|

|