Here is an email from Larry Kelly to the Ducati List. It has many key points about the weaknesses of the Ducati Electrical System. I capitalize the System because anything with a mind of it's own gets a capital on my page. Groan.

From Larry Kelly:

It's a common problem. Here's the basics: HISTORY Ducati voltage regulator-rectifiers (RR∂s) are prone to failure, especially on superbikes. The problem stems from an electrical system design that includes a charging system of marginal capacity on early bikes. This results in constant high electrical demands on the charging system components to maintain an adequate charging rate. The weakest link is the RR. The problem is compounded by faulty stators, poor electrical connections, small-gauge wires, and inadequate cooling of the regulator itself.

When the RRs fail they may also blow fuses and possibly damage the engine control unit (ECU). The Ducati permag type alternator is a design that always puts out 100% power. This output is sent through the regulator-rectifier to be changed from alternating current to direct current. The power is first used for the normal current draw of the fuel pump (~ 5 amps), the radiator cooling fan (~ 5 amps), the headlight (~ 5 amps), electronic ignition (~ 4 amps), computer engine management (~ 2 amps) and other instrument lights, gauges, sensors. The remaining power is then used for charging the battery. After fully charging the battery, the surplus power is then passed to ground. So a normal current output can be 20 amps without even allowing for battery charging. A weak battery will bring this right up to the maximum 28 amps available output by early design alternators. Because of this marginal charging system, early superbikes were designed to run with either the low beam (55W) or the high beam (55W) headlight on, but not both lights simultaneously. If you∂re unfamiliar with how a charging system works, go here first: http://www.electrexusa.com/charging.htm

Not every bike experiences this problem, but some bikes experience multiple failures. Replacing the RR without investigating further is unlikely to resolve the problem. The charging light is the first sign that the RR is about to fail. It will often start to flicker at above-idle rpm's, sometimes requiring progressively higher rpm's to extinguish it. Or, it may just come on and stay on without warning. If this happens while you're on the road, stop and pull the electrical lead wire (under the rubber boot) to your headlight to reduce power demands. If your battery was at full capacity before the RR failure you probably have enough reserve capacity to run your bike for 50 miles or so if you have to limp home. In 1995, after having to replace a slew of 916 RRs under warranty, Ducati made some modifications to their RR and sent them out as replacements. The new versions were marked with a dot of green paint to distinguish them from the older version.

However, RRs continued to fail at a high rate so Ducati redesigned it for 1998. The major improvement was the addition of a large aluminum heat sink to dissipate heat. RRs put out a lot of heat themselves and have integral cooling fins built into their casing to help reject this heat. The additional heat sink, although not finned, was however somewhat reflective and designed large enough to shield the RR from the direct heat from the front cylinder exhaust pipe. Note that if you fit one of these to an older bike you loose the functionality of the charging light. Early Ducati 916/748 alternators are rated at 300 - 350 watts (25 - 28 amps) output. For 1999, Ducati redesigned the electrical system for a larger capacity by going from the 350 watt design to a 500W three-phase system. Three-phase alternators have three wires coming out of them. They produce an AC output that has a higher frequency than a two-phase design so the RR presumably has to do less work conditioning the waveform and converting it to DC. The new alternator has additional wattage available to run the lights, fuel pump, ECU and accessories but the higher output still has to pass through the regulator. The 2001 bikes also have a redesigned fairing with a bigger NACA duct to direct cooling air to the RR. The problem is that it still gets cooked at stoplights from its own heat and the nearby front cylinder exhaust header because there is poor cooling air circulation in the lower fairing. The newer bikes have a revised fairing design with openings on the upper surface that may help convection cooling somewhat.

RECOMMENDATIONS CHECK THE WIRING. Prolonged, excessively high charging currents cause RRs to overheat and fail. So will intermittent circuits from bad wiring and loose electrical connectors. Therefore, it∂s first necessary to check for any damaged wiring. Check for insulation that has been previously heat damaged due to excessive current. Replace any damaged wires with a heavier gauge wire to be safe. The stator wires insulation (all the way back to the casing) is the most likely to be damaged from excessive heat. (The insulation on mine was so damaged by heat that it could be peeled off using my fingernail, even back at the stator.) Install heavier 10-gauge wire to hard wire between the alternator∂s stator and the RR thereby eliminating all the connectors. Note that the stator wires from are encased in an insulation that seals up the two wires and the wires then pass through a oil-tight seal in the engine case. Replacement wires will have to stand up to being bathed in hot oil without leaking. It∂s best to attach the RR∂s negative ground wire directly to the battery∂s negative terminal to assure the best connection and not to some other ground.

CHECK THE CONNECTORS. The number one problem in any motorcycle electrical system is bad connections. Suspect every connection. Disconnect each connector and spray it with a contact cleaner or WD40 before fitting the connector again. Bullet-style connectors should require a firm push to make the connection. If not, use a pair of pliers on the female connector to make it fit tighter. Use a bit of silicone dielectric paste inside the connectors to help them stay free of moisture and corrosion. Replace poor connectors with marine-quality hardware to be sure. Use a multimeter to locate bad connections. A fault-finding procedure is provided here: http://www.electrexusa.com/faultfin.htm

CHECK THE STATOR. Disconnect the alternator wires to the RR and check that the resistance across the wires is 0.2 - 0.4 ohms. Both wires should read infinite resistance to ground. Start the bike and measure the AC voltage across the alternator output wires. It should be 35 VAC at 1500 rpm, rising linearly with rpm (i.e. 70 VAC at 3000 RPM, 105 VAC at 4500 RPM, etc.) Shut off the bike before reconnecting the alternator to the RR. Significant departures from these numbers mean a bad stator, in which case replacing the RR alone will just buy you some time until you fry it too. Electrex has a charging system troubleshooting guide on their website. http://www.electrexusa.com/download/faultfindingchartwebversion.doc

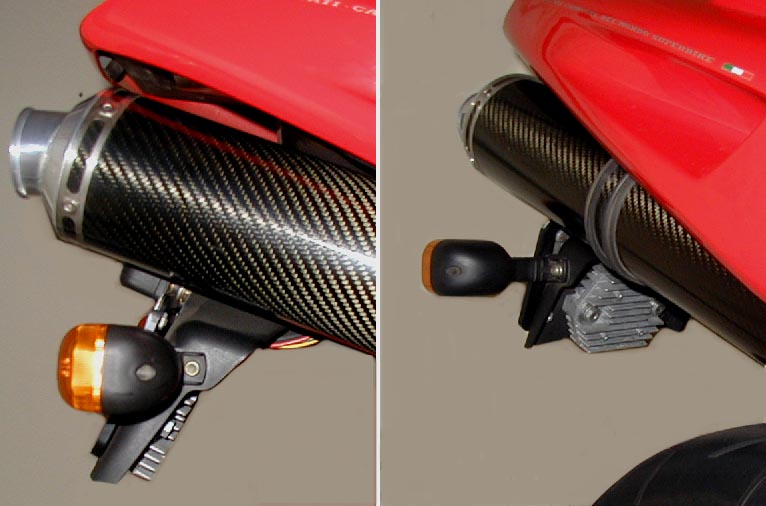

KEEP IT COOL. Heat is the enemy of electrical components. I replaced my fifth failed regulator with a Electrex and moved it to a location outside of the fairing and into the air stream. I extended the wiring and mounted it on the underside of the license plate holder facing the rear tire where it∂s hardly noticeable. All of my previous failures were heat-related. Adding a cooling fan inside the fairing was tried but the ambient temperature in there is just too hot to use as cooling air. I even wrapped the front header pipe in high-temperature insulation (http://www.thermotec.com/tt/exhaust.html) to reduce exhaust pipe heat transfer in the fairing to a minimum but the regulator surface temperature still climbed well beyond 160 degrees at stoplights. Heat is the enemy of solid state electrical components. The regulator itself generates a lot of heat itself so it prefers a cool location, preferably outside the fairing in the air stream. So far so good. The regulator now is only warm to the touch.

INSTALL A DIGITAL VOLTMETER. This gives better information about the health of your electrical system than a charging light. The first thing to check is the voltage at the battery terminals. It should be between 13.5 V and 14.8 V, over the entire rpm range. An on-board voltmeter will flag a RR that is working intermittently prior to failure. Allied Electronic sells a tiny meter (Part No. DVM 572-0002) for $25 that mounts easily. http://www.alliedelec.com/catalog/pf.asp?FN=1019.pdf

REPLACE THE FUEL FILTER. Superbikes use a higher pressure fuel system so the fuel pump runs more often and draws more current. It∂s critical that there not be an obstructed fuel system downstream of the pump. Ducati incorporates an in-line fuel filter inside the gas tank that requires regular replacement (scheduled at 6000 miles). A clogged fuel filter will cause the fuel pump to be overworked and draw excessive current through the regulator-rectifier. A pump with a clean fuel filter will draw about 2 amps, but this figure can rise to 10 amps with a dirty filter.

REPLACE THE BATTERY. If your battery is old or has been replaced with an undersized one then the RR has to work harder to maintain a charge. Avoid replacement batteries that have a lower capacity than the stock battery

USE A BATTERY TENDER. High compression large displacement twins are tough to start but fully-charged battery will reduce post-startup charging demands. It∂s strange that Ducati has never suggested using a trickle charger as a preventative measure. Honda on-line forums have noted similar RR failures and Honda∂s RC51 big twin owners manual makes the suggestion to keep the bike on a battery tender. Curious. I have never seen that in any owners manual before but clearly Honda knows something about their big twin that is interestingly a problem common with Ducati. Honda warns you, Ducati is silent.

REPLACE THE HEADLIGHT. A HID headlight system will reduce the electrical load from 55W to 35W. It will also give you three times the brightness. Baja Designs $355. http://www.bajadesigns.com/Merchant2/merchant.mv?Screen=CTGY&Store_Code=BD-B ike-Store&Category_Code=HID

ELECTREX ALTERNATIVE. The Electrex RR51 is said to be more efficient than the stock component, and costs less (about $150).http://www.ca-cycleworks.com/shop/catalog/ducati/elec.html It has the added advantage of fully charging at about 1800 rpm. The stock begins around 3000 rpm. At idle, battery voltage will be mid 12V∂s rising to 13.9V at speed. Electrex USA says they will replace failed RRs free of change. ELECTREX 2948-A Industry Street Oceanside, CA 92054 Phone (760) 433-0184 Fax 433-1052 email: ritzo@ElectrexUSA.com http://www.electrexusa.com